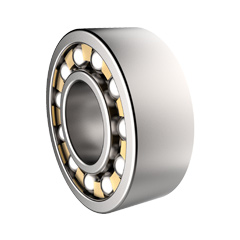

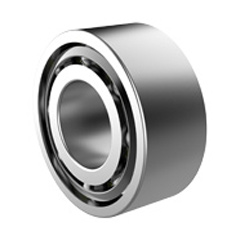

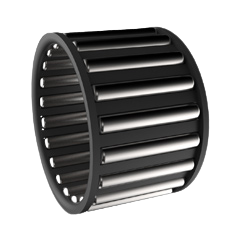

What Are Crossed Cylindrical Roller Bearings?

Crossed cylindrical roller bearing is a common type of rolling bearing, widely used in various mechanical equipment. Its characteristics include the ability to withstand large radial loads and certain axial loads, smooth operation, and long service life. This article will introduce the uses and characteristics of crossed cylindrical roller bearings, and discuss their role and applications in the engineering field.

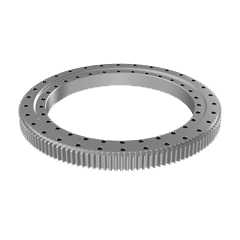

Uses of Crossed Cylindrical Roller Bearings

Large and medium motors

Crossed cylindrical roller bearings are widely used in large motors, able to withstand large radial loads and certain axial loads, suitable for high load and high speed operations.

Machine tool spindles

Due to their excellent radial load capacity and high-speed rotation characteristics, crossed cylindrical roller bearings are commonly used in machine tool spindles, ensuring the stability and accuracy of the spindle.

Automobiles

In the automotive industry, crossed cylindrical roller bearings are used in various transmission components such as axle boxes and diesel engine crankshafts, capable of withstanding heavy and impact loads.

Metallurgical equipment

In metallurgical equipment such as cranes and rolling mills, crossed cylindrical roller bearings can withstand massive radial loads and axial impact loads, ensuring the stable operation of the equipment.

Other mechanical equipment

They are also widely used in vibrating screens, gearboxes, generators, gas turbines, and other mechanical equipment, suitable for various high load and high speed application scenarios.

Characteristics of Crossed Cylindrical Roller Bearings

Strong radial load capacity

Crossed cylindrical roller bearings can withstand large radial loads, suitable for high load mechanical equipment.

Low friction coefficient

Due to the small friction between the rolling elements and the ring flange, they are suitable for high-speed rotation, with a limiting speed close to deep groove ball bearings.

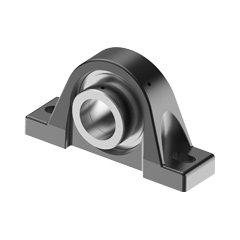

Split structure

The separable design of the inner ring or outer ring facilitates installation and disassembly, reducing maintenance costs.

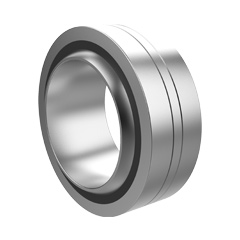

High temperature resistance

They can maintain a certain axial load capacity in high temperature environments and have a certain self-lubricating ability.

Strong impact resistance

Able to withstand large axial impact loads, suitable for working environments with considerable vibration and shock.

Conclusion

In summary, crossed cylindrical roller bearings greatly expand the possibilities for precision mechanical design. Whether it is high-end CNC machine tools, robotic joints, or aerospace instruments, their high rigidity and high accuracy characteristics are indispensable. Choosing crossed cylindrical roller bearings means choosing higher performance standards and broader innovation space.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano