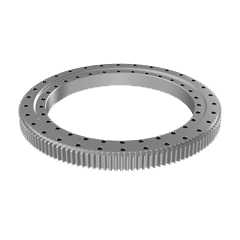

In modern industry, cross roller ring bearings are widely used in fields such as machine tools, aerospace, and robotics due to their high precision, high rigidity, and compact design. However, with the development of technology and the increase in application demands, the performance requirements for cross roller ring bearing are also constantly increasing. This article will explore effective methods to enhance the performance of cross roller ring bearings, ensuring they maintain excellent condition under various harsh working conditions.

Manufacturing of Cross Roller Ring Bearings

Innovative Structural Design

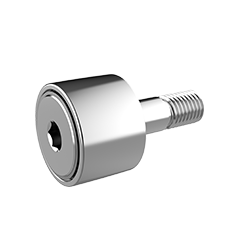

The performance of cross roller ring bearings largely depends on their structural design. By optimizing the arrangement and shape of the rollers, the internal friction of the bearing can be reduced, improving its load-bearing capacity and operational efficiency. For example, using asymmetric roller designs can reduce bearing deflection and improve its rigidity.

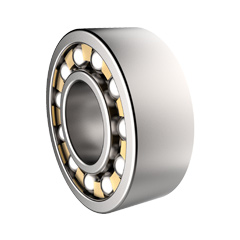

Material Selection and Application

The use of high-performance materials is key to improving bearing performance. Although traditional bearing steel is stable in performance, the introduction of ceramic materials or high-performance alloys can significantly enhance the bearing’s wear resistance, corrosion resistance, and temperature resistance. The application of these materials ensures that bearings maintain stable performance even in extreme environments.

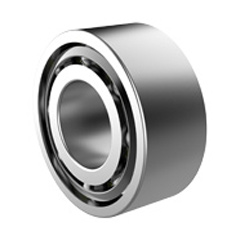

Precision Manufacturing Process

Precision manufacturing processes are crucial for ensuring the dimensional accuracy and surface finish of bearings. By using good CNC machines and grinders, as well as strict heat treatment processes, high-precision bearings can be manufactured, thereby reducing friction and wear during operation and extending the bearing's service life.

Quality Control

Strict quality control is the foundation to guarantee bearing performance. From chemical composition analysis of materials to physical property testing, and dimensional measurement to hardness testing, every step needs to be precisely controlled to ensure that each bearing meets standards.

Performance Testing

Comprehensive performance testing is an important step in enhancing bearing performance. By conducting tests on dimensional accuracy, load-bearing capacity, friction coefficient, and life prediction, the performance of bearings can be fully evaluated and optimized accordingly.

Preload Adjustment

Proper preload can eliminate internal gaps in the bearing, enhancing its rigidity and accuracy. By accurately adjusting the preload, bearing deflection and vibration can be reduced, improving its positioning accuracy.

Lubrication System Optimization

Lubrication is key to the normal operation of bearings. Choosing suitable lubricants and lubrication methods can significantly reduce bearing friction and wear, extending its service life. At the same time, regular lubrication and cleaning are also important measures to maintain bearing performance.

Integration of Intelligence and Automation

With the development of smart manufacturing, the intelligence and automation of bearings have become important means to enhance performance. By integrating sensors and monitoring systems, real-time status monitoring and fault pre-warning of bearings can be achieved, improving equipment operational efficiency and safety.

Continuous Improvement of Maintenance and Service

Regular inspection, cleaning, lubrication, and replacement services are crucial for maintaining bearing performance. By providing professional maintenance services, potential issues can be timely identified and resolved, ensuring the long-term stable operation of bearings.

Technical Methods

Surface Treatment Techniques

Such as coating, plating, carburizing, and heat treatment can improve the surface quality of bearing steel, enhancing its wear resistance, corrosion resistance, and friction performance.

Surface Deformation Strengthening

Methods such as shot peening, sandblasting, cold extrusion, and rolling can increase the surface fatigue strength of cross roller ring bearings and reduce the sensitivity of fatigue notches, thereby extending the service life of bearings.

Surface Heat Treatment

Surface heat treatment methods such as flame heating quenching, high (medium) frequency induction heating quenching, laser heating, or electron beam heating quenching can improve the hardness and strength of bearing steel, enhancing its wear resistance and load-bearing capacity.

With the continuous advancement of technology and the increasing industrial demands, the performance enhancement of cross roller ring bearings has become an important topic in the industrial field. Through the above measures, we can significantly improve the performance of cross roller ring bearings to meet more stringent working conditions and higher industrial standards.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano